| SM Publications |

| Silver Salon Forums - The premier site for discussing Silver. |

| SMP | Silver Salon Forums | SSF - Guidelines | SSF - FAQ | Silver Sales |

|

|

|

The Silver Salon Forums

Since 1993 Over 11,793 threads & 64,769 posts !! General Silver Forum

|

| REGISTER (click here) |

How to Post Photos

|

|

SMP Silver Salon Forums SMP Silver Salon Forums

General Silver Forum General Silver Forum

Engine Turned? Is it or not? Engine Turned? Is it or not?

|

| next newest topic | next oldest topic |

| Author | Topic: Engine Turned? Is it or not? |

|

ringboxlady Posts: 95 |

[01-0742] I have been told that this box is "engine turned" on top. Is this the correct wording for what this box has on the top? If it's not "engine turned" what is it and how is this done? Thanks! IP: Logged |

|

wev Moderator Posts: 4121 |

Can we get a close-up of the top? Engine turning will produce extremely regular line spacing, curves, and line width, but we need to see it -- I had an old friend, sadly gone, who could, at first glance, engrave as well as an engine turning machine. Some indication of date would help as well. [This message has been edited by wev (edited 07-09-2002).] IP: Logged |

|

ringboxlady Posts: 95 |

I can't get a closer picture without a terrific glare. The marks on the bottom are HP&S, Lion passant,either a crest or erased lions head, lower can "n". Can you figure out what year that is? If I looked it up correctly, which is not guaranteed, I see it being dated as 1912-1913. Let me know. What time frame are we looking at when engine turning was started? Good to chat with you again, Thanks! I noticed something else, the tiny lines look very even and BUT the larger stripes are uneven and now that I really look at that aspect, it doesn't look exactly centered. IP: Logged |

|

wev Moderator Posts: 4121 |

Try this link: About Engine Turning for a lovely page of pattern examples. I believe (but know less about it than I should) that the first machines were developed in the 1820s. They were very labor intensive and demanded high skill -- hence only first rate goods -- watch cases, serving pieces, currency plates, etc got the treatment. Fully automatic machines became standard in the 1860s and the practice became more wide-spread. IP: Logged |

|

ringboxlady Posts: 95 |

Thanks for the directions to the samples. I think mine is more detailed. It has the circle in the middle with the script monogram, 2 different types of stripes and then has a border around the outer edge. Would a ring box have been considered a first rate good at that time? IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

quote: You might want to try an old photographing silver trick. Try putting the object into a freezer to get cold. When you take it out, humidity will create a glare reducing coating. This coating will only last a few moments so shoot quickly. If you are in a very dry climate you might try photographing in the bathroom after someone takes a hot shower. IP: Logged |

|

ringboxlady Posts: 95 |

this is as good as it gets from my end.  IP: Logged |

|

Paul Lemieux Posts: 1792 |

Just FYI--engine turning is still used today. A year or so ago, when I was still on Tiffany's mailing list (I was only in it for the free catalogs), I noticed they advertised engine turned buckles, business card cases, etc. The engine turning was just straight lines, not the fancy stuff found on some mid Victorian silver. [This message has been edited by Paul Lemieux (edited 07-10-2002).] IP: Logged |

|

wev Moderator Posts: 4121 |

Pretty good shot; It looks like standard turn of the century engine turning to me. As for how it's done, you can look here: Engine - Turning "Guilloche" which has a not-to-technical explanation and a couple of very bad videos. From my web searches, it appears that true (ie hand controlled and complicated as hell) engine turning has a real dedicated following keeping the craft alive. One problem (and I know how they feel, being a letterpress printer) is that the 'real' machines haven't been made since the 1940s. Basic, hands-off machines (ala Tiffany) are still available, but looked upon with scorn. IP: Logged |

|

ringboxlady Posts: 95 |

Thank you Scott for the photo trick and thanks wev for the link on engine turning. Great info there. I really appreciate you guys helping me out. Thanks, c IP: Logged |

|

Trefid Posts: 96 |

There is a picture of an engine-turning machine ca. 1878 on page 87 of Venable's Silver in America: 1840-1940. I got to see one of these machines rusting outdoors once upon a time, but I wasn't mechanical enough to figure out how it worked. What I don't understand is how the machine was guided so that the e-t'ing didn't run over engraved areas or other areas to be kept pristine. E-t'ing for circular objects like watches and compacts was done on something called a "rose engine." This was a different machine from the one in Venable. IP: Logged |

|

ringboxlady Posts: 95 |

Hi Trefid, Thanks for your tidbit on engine turning. I myself would love to see one of the machines which did this intriguing detail. Better yet, I would have loved to have seen it back in it's time actually being done. I'll have to see if I can look up the book you mentioned. Thanks again, IP: Logged |

|

jt251 Posts: 25 |

[26-1797] The fascinating Musee des Arts et Metiers in Paris has a rose engine lathe that was made by Mercklien in 1780. The museum's website has a video showing how the machine works. You can go to the video by doing a search on (or click here): Tour a guillocher de Mercklien and looking for the museum site. There is an English translation available on the video page to make it easier to find the Mercklien Rose engine. IP: Logged |

|

jersey Posts: 1203 |

Hello jt251! It was a wonderful experience! Thank you. Jersey IP: Logged |

|

Kimo Posts: 1627 |

It is so hard to tell from the fuzzy photo but from what I can see it is a simple engine turning design. If you can post a clear photo of the hallmarks we might be able to give you a better idea of its age but turn of the century to first quarter of the century sounds about right for the design and form. As for whether it was a first rate good when it was made I guess that depends on what you consider to be first rate. I would think anything made of sterling in that era would be considered generally by the people back then to be first rate, but depending on the maker and the quality of the detailing and thickness of the metal it could be anything from a relatively modestly priced ordinary object affordable to the middle class to a very costly luxury object afforded to only the wealthy. For example, a top of the line object may have gold inlays set into the metal and perhaps a jewel or two also inset, or elaborate designs in the engine turning, or some enamelling, or engine turning not just on the lid but also on the body of the box, or a gold wash inside, and refinements of this sort that turn it into a real artwork. Look at some of the work by Cartier, Tiffany, Faberge, and other high end makers and retailers to see what I mean. IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

See:

IP: Logged |

|

middletom Posts: 467 |

All that I have ever seen referred to as "engine turning" has been circular abrasions in rows, touching one another. I gather from the discussion that there are various types of "engine turning" patterns of stripes and such. The circular abrasions that are referred to as "engine turning" I've read is correctly called Damascening for it was often used on Damascus steel weaponry. Because that work dates back a long way it was probably done by hand originally. middletom IP: Logged |

|

ahwt Posts: 2334 |

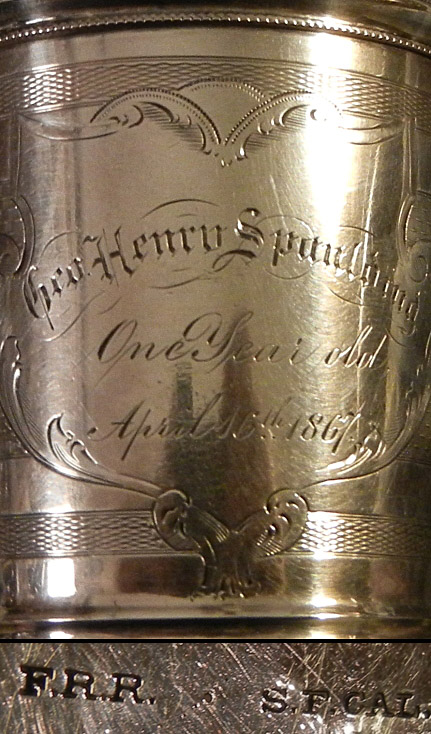

Engine turning decoration was very popular on presentation cups made in the 1850s and 1860s in the United States. Above is a group of presentation cups with the four on the left having engine turning while the one on the right has conventional engraving. From the left they are marked JLW (engraved Charles from his Grandmother), Albert Cole (engraved H. Rosenfield), PLK Standard (engraved Jamie), FRR S. F. CAL (engraved Geo. Henry Spaulding One Year Old April 16th 1867) and S. Kirk and Sons 11OZ (engraved Melville Wilson from his Great Grandmother). IP: Logged |

|

ahwt Posts: 2334 |

The John Westervelt cup for Charles is below: IP: Logged |

|

ahwt Posts: 2334 |

The Albert Cole for H. Rosenfield is below and this one has the most complex engine turning:  The slope of the side of this cup and the hand engraving incorporated within the engine turning must have presented a challenge to create. IP: Logged |

|

ahwt Posts: 2334 |

The Peter Krider cup for Jamie is below and has engine turning very similar to the Westervelt cup; IP: Logged |

|

ahwt Posts: 2334 |

The Friedrich R. Reichel cup for George Henry is below:  I suspect that this cup was made on the east coast rather than in San Francisco, but I really do not know much about silver from this area. IP: Logged |

|

ahwt Posts: 2334 |

The Kirk cup for Melville does not have engine turning, but the repetitive engraving (that I think was entirely done by hand) is reminiscent of engine turning. I usually search for this one for punch as it holds just the right amount. IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

Thanks so much for sharing this great collection of cups. I am wondering if Grandma on the Westervelt cup is the same Grandma in A gift from Grandma Westervelt? IP: Logged |

|

Kimo Posts: 1627 |

Very nice cups! Middletom, I am not sure but I had always thought that damascening was different from Damascus steel? My understanding is that damascening is a technique where a smith takes some dark colored oxidized steel and hammers gold or silver into it in arabesque designs that is reminiscent of damask silk tapestry designs. And that Damascus steel is where an iron smith takes a lump of iron with many carbon and other impurities and hammers it into a blade in such a way as to preserve the mix of high and low carbon areas in the iron making a resulting swirly mix of high and low carbon steel. Then when it is filed and polished the surface reveals that swirly mix as it was created by the different areas of higher or lower carbon steel that are naturally slightly different colors (darker and lighter) and that are affected by skillful hammering patterns of the smith to reveal a water/wave-like patterning in the steel. This mix of high and low carbon areas throughout the steel is what allows such a blade to hold a razor sharp edge while having the ability to flex and not break when striking another blade or some armor. It is similar in concept to, but different from old Japanese samurai blades that are made from many layers of high and low carbon steel. In talking about this, I have just started wondering whether silver might be smithed in such a way as to take two alloys of silver, each with a different coloring to them, and hammer weld them into a mutilayer bar, fold it over on itself several times to get 64 or 128 layers and then shape it into an object that once it is completed and shaped and polished would reveal that wood-grain like patterning that japanese swords have. Has this already been tried or is there a reason why it would not work? [This message has been edited by Kimo (edited 08-29-2012).] IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

quote:Kimo's explanation is generally what I have heard before. I suspect he is correct.

quote:The technique is called Mokume or Mokume Gane or Mokume Gani. IP: Logged |

|

middletom Posts: 467 |

Kimo, You are probably correct as to the derivation of the name. I read the damascening explanation in a book about old cars by the late Ralph Stein. He mentioned that the swirl pattern often used on upper level cars for dashboards and such, for instance on Duesenbergs and Bugattis, was commonly called "engine turning" whereas the proper term is damascening. However, I have never before seen the type of complicated designs as shown above. The designs shown there are stand up patterns and lines which simulate engraving. Not at all what I had in mind. Why is it called "engine turning" when the designs shown were not, apparently, turned? middletom IP: Logged |

|

ahwt Posts: 2334 |

The Rose engine is a specialized kind of lathe that produces geometric patterns. I suppose the phrase “engine turning” came from the use of the word “engine” for a machine with moving parts and turning came in as the machine is a lathe that turns objects to create a finished product. I do not know how a silver cup was held by such a machine as the movies Scott referenced all show flat objects being turned. It seems to me that many of the patterns produced have a moiré design look. IP: Logged |

|

Kimo Posts: 1627 |

Thanks Scott. I figured someone would have tried it and it makes sense that the Japanese silver smiths are among the leaders in it. Middletom, the objects that Scott shows get that patterning on the surface from the process I describe - taking sheets of different color alloys of metal and hammer welding them into a sandwich which you fold over on itself several times to get many layers, then with great expertise hammering the resulting bar with a smaller hammer that deforms the layers in artful ways to make the layers not entirely parallel, then filing the result down to reveal the internal deformed structure and polishing it. The designs are the surface expression of the layers of different color alloys in the object. It is a little bit like what you see when you take a piece of wood, carve it and polish it and then seeing the wood grain exposed in pleasing patterns, except you can not deform the wood in artful patterns by hammering it. Here is a photo of a smith making a damascened plate. He is inlaying gold and silver into darkly oxidized steel.

IP: Logged |

|

ahwt Posts: 2334 |

The cups above show a moiré pattern common on fabrics and accomplished on silver with engine turning. I knew I had some of this pattern, but I had forgotten it was on wine goblets rather than cups. These goblets were presentation gifts as they are inscribed to Jenny from Sylvester Oct 11, 1860. The moiré pattern may be the most striking of all the patterns made with the Rose engine. IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

Got an extra 8,500.00 get your own Engine Turning Machine. FA Hall Straight Line Engine Ornamental Turning Engraving Guilloche Machine [This message has been edited by Scott Martin (edited 08-26-2021).] IP: Logged |

All times are ET | next newest topic | next oldest topic |

|

|

Ultimate Bulletin Board 5.46a

|

1. Public Silver Forums (open Free membership) - anyone with a valid e-mail address may register. Once you have received your Silver Salon Forum password, and then if you abide by the Silver Salon Forum Guidelines, you may start a thread or post a reply in the New Members' Forum. New Members who show a continued willingness to participate, to completely read and abide by the Guidelines will be allowed to post to the Member Public Forums. 2. Private Silver Salon Forums (invitational or $ donation membership) - The Private Silver Salon Forums require registration and special authorization to view, search, start a thread or to post a reply. Special authorization can be obtained in one of several ways: by Invitation; Annual $ Donation; or via Special Limited Membership. For more details click here (under development). 3. Administrative/Special Private Forums (special membership required) - These forums are reserved for special subjects or administrative discussion. These forums are not open to the public and require special authorization to view or post. |

|

copyright © 1993 - 2022

SM Publications

All Rights Reserved. Legal & Privacy Notices |