|

|

|

| How to Post Photos |

REGISTER (click here)

|

|

|

|

| How to Post Photos |

REGISTER (click here)

|

|

SMP Silver Salon Forums SMP Silver Salon Forums

American Sterling Silver American Sterling Silver

Gorham Plant Art In Ruins Providence, RI Gorham Plant Art In Ruins Providence, RI

|

| next newest topic | next oldest topic |

| Author | Topic: Gorham Plant Art In Ruins Providence, RI |

|

bascall Posts: 1629 |

[01-2643]

quote: IP: Logged |

|

argentum1 Posts: 602 |

I live in a medium sized town of appx. 26,000. The high school building I attended was built in 1931. After a school board meeting it was decided to build a new high school. According to the board the old building would be too expensive to upgrade and the roof was supposed to be leaking. I do not remember any leaks nor have I ever heard or read in the newspaper about a leaky roof. Well, after a million and a half dollars we had a new high school building with a leaky roof within 8 months. As far as I can find out the old building still has no leaks as well as being architecturally more pleasing - at least to my old tired eyes. Once again I say the same thing I have said for a long time - people here have taste but it is all in their mouth. By the way, the new high school is a series of 4 plain boxes sat next to each other. IP: Logged |

|

Brent Posts: 1507 |

If you go through Meriden, CT, you can see at least one old silver company buliding that was converted into loft apartments. There are still a few others that could be. Brent IP: Logged |

|

June Martin Forum Master Posts: 1326 |

On Maiden Lane in downtown New York city, you can still faintly see on the top side of one of the buildings the words "Silversmiths Building." Many silver notables operated out of this building. IP: Logged |

|

agleopar Posts: 850 |

Bascall, I got to see Gorham from the outside just before they pulled the plug. A few years latter I had the pleasure of working for 6 years in a fourth floor west facing workshop over looking the Charles river in the old Waltham Watch Co. building. It is the same vintage as the Gorham building was and covered 5 city blocks (square for three)! It still stands today and will eventually make its owners a lot of money because it is so well built and is close to Boston. As an example one of the 100 ft. smoke stacks had a crack in it (land lord could only see the liability) and the company that bid on taking it down lost a lot of money because the crack turned out to be superficial and the thing was 5 times stronger than they estimated. The foreman told me he thought it would have stood, with the crack, for 300 years. I cannot talk about Gorham with out getting sick about the waste... The building, the tools, the dies! If I were king the numbskulls who thought they were protecting the Gorham name by dumping the above should be made to - to - - Argentum, do you live in Hillsdale, NY cause that exact same school situation has happened there too!? IP: Logged |

|

Polly Posts: 1970 |

I used to live around the corner from the old Ansonia clock factory in Brooklyn. Condos. At least the building's shell still stands. IP: Logged |

|

argentum1 Posts: 602 |

Agleopar, I live in Ohio. This situation exists for any number of reasons. Although members of school boards are well intentioned they appear not able to see the value of 'old' but quite structurally sound buildings. Columbus, Ohio started saving and recycling their old buildings about 25 years ago with a lot of success (financially and architectural appeal). I imagine that if the pyramids were here they would have been torn down a long time ago. I, personally would much rather live or work in a nice old Victorian or earlier structure than inhabiting the penthouse of a very tall and sterile rectangle IP: Logged |

|

bascall Posts: 1629 |

Thank you all for your comments. This may have been discussed in past postings, but it seems to me, believe it or not, that the end of sterling and silver usage on a large scale coincided with advent of permanent press. Automatic this and that and quick and easy just didn't seem to make any extra time for such things as fine silver for the majority. People were determined not to be tied down to the same chores that their mothers and fathers performed. Maybe someday folks will wise up to their heritage. My turn on the soap box is over for now. "Speakers corner" is yeilded to the next lady or gent. IP: Logged |

|

jersey Posts: 1203 |

You all know the expression about what hindsight is......... I'm sure we have all been guilty of tossing things out with deep regrets later on. I am Numero uno on that hit parade, and now my kids are screaming.........enough already Mom! If wishes were horses I'd have a stable full. Jersey IP: Logged |

|

Kimo Posts: 1627 |

I don't have one, but I believe Gorham made a souvenir spoon with a view of their factory in the bowl. Re-using old buildings is becoming more common, but it can be much less profitable than bringing in a bulldozer and which allows a developer to pack in the maximum number of houses that are designed for the local market. Often a community needs to offer incentives to developers to re-use old buildings. IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

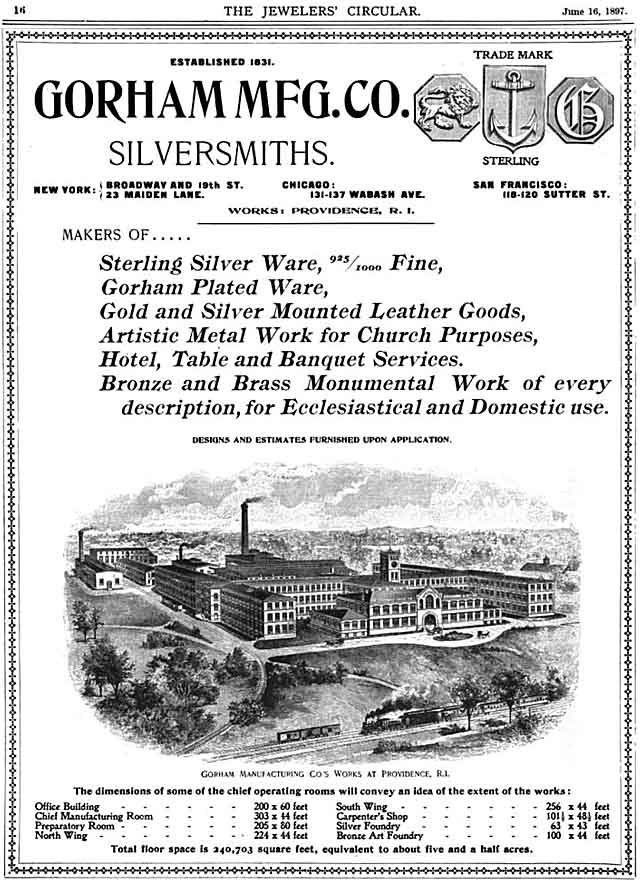

Excerpt from the bio of

Page 290 NEW ENGLAND MANUFACTURERS AND MANUFACTORIES Vol. 1 1879 JABEZ GORHAM — JOHN GORHAM Until late in the first half of the present century, the manufacture of silver-wares was not begun in this country, except in a limited way, in the making of spoons and other small articles. From the foundation laid by Jabez Gorham, in Providence, R. I., John Gorham, his son, and Gorham Thurber, his nephew, twenty years after inaugurated the new era in this business ; and in twenty years more they had established a large and representative industry. Jabez Gorham was born at Providence, R. I., Feb. 18, 1792, and was descended from John Gorham, who came from Northamptonshire, England, in 1643, and settled in Plymouth, where he married Desire Howland, daughter of John Howland, one of the Pilgrims, born a short time after the landing on Plymouth Rock. The father of Jabez was a Saddler, and died when Jabez was about fourteen years of age. The latter attended the free schools in his early years; and soon after his father's death was apprenticed to Nehemiah Dodge, who had begun business as a manufacturing jeweler in Providence, in 1795. Here young Gorham served seven years. Soon after attaining his majority, he entered into partnership with Christopher Burr, William Hadwen, George G. Clark and Henry G. Mumford. Their business was fairly successful for five years, when they dissolved partnership, the several members forming other connections. Mr. Gorham continued the business alone, and took the premises previously occupied by the firm, at the corner of North Main and Steeple Streets, Providence. A year or two later he removed to a shop which he had purchased on Steeple Street; and this was the nucleus of the range of buildings now occupied by the Gorham Manufacturing Company. Here Mr. Gorham pursued the manufacture of jewelry until 1831, making gold beads, earrings, breast pins and finger-rings, and a peculiar kind of gold-chain which gained some reputation as the “Gorham chain." He disposed of his goods in part to peddlers; and twice a year he visited Boston, to supply his customers in the trade there. In 1831 Mr. Gorham's attention was turned to the manufacture of silver spoons. These had been made for many years by silversmiths; but the demand had been limited. It was only a short time before the Revolution (about 1760), that, even in England, silver tablespoons had begun to take the place of spoons of wood, horn and pewter on the tables of the wealthy; and silver teaspoons were rare before the time of Queen Anne (1691-1713); but, in the first quarter of this century, families in comfortable circumstances were accustomed to have a set of teaspoons, and, perhaps, half a dozen tablespoons, of silver. The silversmiths mostly confined themselves to orders from dealers in jewelry, who rarely purchased more than one or two dozen at a time, and for special orders; but about 1825 they began to manufacture light spoons for general sale through the cheap jewelry peddlers. Mr. Gorham now engaged a young man, Henry L. Webster, who could make silver spoons, to go to Providence, and ‘start the business in partnership; and a firm was formed, under the name of Gorham and Webster. The business begun modestly, Mr. Gorham's jewelry manufacture being continued as a distinct interest; and the process was extremely crude. A bar of silver was heated in a common blacksmith's fire, rolled to the proper thickness by rolls operated by a Windlass, and then hammered into shape. Each spoon had to be made hot nine times before it was finished. By hard work, two men could make in a day two dozen teaspoons — no two, however, alike, in shape or weight. For nine years nothing was made but spoons, thimbles and silver combs, and an occasional napkin-ring or fork. At fifty Mr. Gorham retired from the business, being succeeded by his son John. He had often been called to positions of financial or political responsibility by his fellow citizens; but, during the last twenty years of his life, his retirement from public, as well as mercantile, interests was complete. He died suddenly on March 24, 1869, at the age of seventy-seven. John Gorham was born in Providence, Nov. 18, 1820. He attended the city schools, and, when seventeen, went into his father's shop to learn the trade of a manufacturing jeweler. Early in 1837 he determined to try his fortunes elsewhere. He first went to Smithfield, R. I., where he remained the rest of that year, working on a farm; and the next three years he spent in Providence, New York and Boston, as clerk in different branches of trade. At the end of that period he returned to his father's shop as partner, with the superintendence of the work. The firm was re-organized as Jabez Gorham and Son, Mr. Webster retiring, and returning to Boston, and his interest in the tools, shops and business being purchased by the new firm; and John Gorham assumed charge of the concern. The business steadily increased; the senior gradually withdrew from active participation in it; and, in 1847, John Gorham found himself its sole proprietor. He now purchased a steam-engine and set it up, and erected an additional building in the rear of the old shop. In 1850, believing that there was a profitable field in silver manufacture not yet occupied, John Gorham determined to enter it. This was the manufacture of silver hollow-ware (the technical name by which all goods of the general form of pitchers, teapots, etc., are designated, the term flat-ware being applied to forks, spoons, and other similar articles) on a large scale; and also of every article of silver for which a demand arose, whether for ornament or utility. Mr. Gorham now invited his cousin, Gorham Thurber, to become a partner with him; and a co-partnership was formed Feb. 1, 1850, under the style of Gorham and Thurber. Gorham Thurber was the son of Dexter and Hannah (Gorham) Thurber, his mother being the sister of Jabez Gorham ; and he was born in Providence, R. I. on April 9, 1825. He went, in 1841, into the office of the Franklin Foundry and Machine Company, which had been established, in 1836, by Isaac Thurber and others, and of which Isaac was the manager. Here he became book-keeper, and this position he occupied until he became a partner in the firm of Gorham and Thurber. The arrangements for the extension of the business having been effected, Mr. Gorham hired an artisan skilled in the working of hollow-ware, procured tools, and soon had this new branch of manufacture in progress. In order to avail himself of every appliance to improve his work, or to economize labor, he first visited various establishments in this country—among them the United States Arsenal, at Spring field, and the Mint, at Philadelphia ; and then in May, 1852, made a trip to Europe, to observe machinery and methods. Meanwhile, Lewis Dexter, also a cousin of Mr. Gorham, was taken into the firm; and its name was changed to Gorham and Company. Mr. Gorham visited the great shops of Elkington & Co., of Birmingham, the shops of Dixon and Sons, of Sheffield, the Government Arsenal, at Woolwich, the Mint, at London, and shops in Paris and Brussels. The result of his observations satisfied him that he had nothing to fear from English or European competition in the use of machinery; as, in this respect, they were not only far behind our manufacturers, but very much that was done by them by hand was more effectively done in this country by machinery. He was also satisfied that, in manipulation, and in all processes which depended on expertness and care in hand- labor, they were much in advance of us. This was especially true of molding metals for fine work. That he might become an adept in this difficult branch of metallurgy, he entered an establishment in London where work of this kind was done, and paid for the privilege of working by the side of a skillful molder; and for three weeks he wrought like any operative, until he had mastered the art. He also hired and sent to Providence as skillful a molder as could be obtained, and several other thorough artisans in various branches of metal-working. On his return home, in 1852, the business received a new impulse; and, until the beginning of the Civil War, it rapidly increased, the goods manufactured being distributed to every part of the country and in Canada; and, during the latter part of this period, a large trade was established with California. In 1854 George Wilkinson, who had learned his trade as a die-cutter in Birmingham, England, and had also given his attention to designing and modeling, was hired as a die- cutter. He soon became an accomplished designer and modeler, and at the present time he is the superintendent of the designing-rooms, in which a large corps of assistants is employed. Early in 1861 about two hundred hands were employed in the establishment. In that year Mr. Dexter retired from the firm; and business was continued by the other partners, the name of the firm remaining unchanged. During the early months of the war, the market for the firm's goods was greatly curtailed, at the same time that the cost of the goods manufactured was nearly doubled, by the increased premium on silver and the great advance in wages. The firm then turned its attention at first to the manufacture of bronzes; but in 1863 it applied its resources, machinery and patterns to the production of plated-ware of the highest grade, and now known as “Gorham plate." Its base is nickel, which now rivals silver for so many purposes, with only sufficient alloy to reduce its refractory temper to the necessary malleability. The process which, in the hands of the Elkingtons in England, and of Gorham and Company and others in America, has brought silver-plated ware within the reach even of persons of moderate means, was developed, in 1840, from a discovery made about 1800. Joseph Shore, of Birmingham, England, was the first to bring about a practical result, and a patent was issued to him March 3, 1840, the claim for which is as follows: “This invention relates to a mode of obtaining or applying a permanent covering of copper, or nickel, on articles manufactured of wrought or cast iron, tin, lead and copper, and of alloys of such metals, such covering acting as a preservative to some of those metals and alloys of metals, and, in other cases, as a superior surface." On the 25th of March, 1840, a patent was granted to George R. and Henry Elkington, of the firm of Elkington and Company, of Birmingham, England, the second claim of which was for “coating certain metals with silver by the use of a silver solution only, also by means of a solution of silver in connection with a galvanic current. The solution consists of oxide of silver dissolved in a solution of prussiate of potash (cyanide of potassium). This solution is used boiling. The same solution may be used cold when electric force is applied." The third claim of the patent was for similar processes of coating with gold. This process was substantially the same as that now in general use. The silver-platers of Birmingham and Sheffield, who used the old processes, by soldering and filming, ridiculed the new Elkington process, and prophesied its failure, their opinion being that this new method was only a kind of washing, and that the plating would soon wear off. This opinion has been demonstrated to be erroneous. The advantages of the new process were, that the metal being plated after, instead of before, manufacturing, all restrictions in taste and design are removed ; and that the different parts of the article, which have been already electro-plated, can be united, if desired, by hard silver solder (two parts of silver and one of brass), which is not affected by any degree of heat that would not be fatal to the metal contained in the article itself. In the old method, soft solder being used, the silver film on spoons, and the ornaments which had been affixed, would often, in ordinary use, become detached. Any pattern, moreover, which can be executed in silver can be as readily made in the metal which is to be plated; and old goods, in which from long use the plating has been partially or wholly worn off, can be restored at a small expense. The first American manufacturer who engaged in making electro-plated goods was Asa Rogers, a silversmith in Hartford, Conn. He established, in 1842, a small factory at East Granby, Conn., and began to make electro-plated spoons and forks, and other flat-ware, the base being britannia-metal. He had thoroughly established himself in 1847, when he formed a partnership with his brothers, and produced goods of such excellence that the trade-mark, “Rogers Bros., 1847," was imitated extensively, and was afterward purchased, at a high price, by the Meriden Britannia Company, then engaged in the manufacture of electro-plated hollow-ware, with abase of britannia-metal. The first manufacturer of electro-plated hollow-ware in this country was Samuel Simpson, of Wallingford, Conn. He began the manufacture in 1848, also using the britannia—metal for the base. Gorham and Company, at the outset of their business in electro—plating, used, as has been stated, the nickel silver as their base. In January, 1865, the Company was organized as a corporation, the two members of the firm being the principal corporators. John Gorham was chosen President, Gorham Thurber, Treasurer, and J. F. P. Lawton, Secretary. The capital stock was at first fixed at $300,000, with a limit of $600,000; and in May, 1872, was increased to $600,000, with a limit of $1,200,000. During the ten years following the incorporation of the Company the business steadily increased. In 1872 the number of hands employed was four hundred and fifty, and the shops and rooms for the various purposes of the business had been multiplied so that they covered the whole area bounded by North Main, Steeple, Canal and Friend Streets, except a small building, 60 feet by 40, on the corner of North Main and Friend Streets. In January, 1878, Mr. Gorham retired from the office of president, and was succeeded by William Henry Chins. Mr. Thurber still holds the office of treasurer, and Mr. Lawton that of secretary. The first lesson learned by Messrs. Gorham and Thurber in their enterprise, was, not only that machinery might be introduced with advantage, but that silver ware could not be made with jewelers' tools. There must be special adaptations of machinery used by other metal-workers. They established a shop, 80 feet by 40, for repairs and the building of new machines; and this was amply furnished with tools, and an auxiliary steam-engine; so that, if necessary, the shop could be run independently of the rest of the works. Many machines have here been devised, patterns made, and machines built. Every apparatus and arrangement for the convenience and economy of labor have also been furnished. Steam-engines drive almost innumerable lines of shafting. Steam-elevators and pipes throughout afford communication, for heating or lighting, conduct gas, air-blast, live and exhaust steam, and hot, cold, hard and soft water. There is a great variety of machines for rolling, shearing, milling, punching, shaping and embossing; ponderous die-stamping machines, lathes, drills and planing-machines for wood or metal ; foundries for casting iron, brass, silver, gold and other metals; a blacksmiths' shop; large rooms devoted to melting and refining furnaces, electro-plating and gilding, photography, and metal spinning; apartments occupied by artists and draughtsmen, by engravers, chasers, embossers, die-cutters and die-hardeners, tool-makers, weighers and packers, and fancy case-makers in wood, morocco and velvet. Excepting a few workmen and artists of special training, the Company employ intelligent American youths, and, in many cases, men who had been educated to other work. In the establishment at least twelve distinct trades are carried on, to each of which boys are regularly apprenticed. It is a trade to make spoons, forks and other flat-ware ; and designing, die-cutting, pattern-making, stamping, molding, embossing, engraving, chasing, plating, burnishing and polishing are all separate trades. In every country it is the rule that the standard for silver-plate shall be the same as that of the silver coin of the country. The coin of the United States and of France being nine hundred parts of silver and one hundred parts of copper, the genuine plate of those countries has conformed to that standard. English coin is nine hundred and twenty-five parts silver to seventy-five parts copper; and English plate, when honestly made, is of that degree of purity. To this standard has been applied for nearly seven hundred years the word now so familiar, sterling. Sterling plate is really no better for the purposes to which it is applied, except in pecuniary value, than American coin plate. The Gorham Company, however, adopted the sterling standard. When silver is received at the factory, its exact weight and purity are recorded. But the character of no silver is taken on trust. Coin was, at one time, the form in which silver was bought for manufacturing purposes. The first thing done at the factory was to pick out counterfeit coin. In American coin there have usually been four or five counterfeit pieces in the thousand; in that which comes directly from the mints of Mexico and Peru, a counterfeit is seldom found. Every coin was subjected to a process which twisted it asunder, and then dropped it on the heap below. If it was false, the fact was discovered by the manner in which it tore apart, and by the ring as it struck the mass of silver. When the broken coins were placed in the crucible to be melted, enough pure metal was added to bring the mass a little above the sterling standard. Thus the Company was also obliged to buy a certain quantity of pure silver, to raise the standard to sterling. For ten years bullion has mostly been used. This is usually brought to New York in small, rough, silver bricks, each one assayed and worked by the assayer at the mint 998 or 999, and very rarely 999. Perfectly pure silver is scarcely ever sold in the market. The stamp of the Gorham Company is as good guaranty of sterling purity as the “Hall mark ;" which must, in England, be affixed, after an assay, by an officer of the government before the wares can be sold as silver. The same course has been taken in the manufacture of the plated-ware. Only the best base is used, and the largest quantity of silver is deposited on it. The Gorham Company lays a silver surface upon the ware, and thus produces ware with the splendor of the best plate, at about one-fourth the cost. Its patterns, ornaments and workmanship are similar to those of the Gorham Sterling Silver. Its surface is a thick coating of pure silver. The policy of the Company has been to make, not only pure, but artistic, goods. The designing-room of the Company is stored with books, including many costly works, illustrative of designs and patterns of plate and silver-ware. In their earlier history, the Company did not venture to abandon the forms approved by habit and protected by fashion. They modified, or laid aside, a fine design, because it was too simple, or too violent a departure from established patterns. But now the public taste has greatly advanced, and demands a higher grade of design and of workmanship than European silversmiths usually produce; and with this progress the Company has kept apace. IP: Logged |

|

asheland Posts: 935 |

Great thread here! IP: Logged |

|

wessex96 Posts: 56 |

It is interesting to note that although all the buildings housing the massive Gorham production facility in Elmswood, Providence have been demolished, the relatively small building that housed the Gorham factory in England still stands. From 1909 to 1921 Gorham had a small factory in England producing items in both sterling and electroplate silver. It was located within a part of a late Victorian building, dating from the 1880s, which was built for and occupied by the watch manufacturer, William Ehrhardt. The building has three wings that extend out from the rear. Gorham occupied the left wing, the wing that can be seen in the photo. The overall building complex still has the name ‘Time Works’ carved in stone blocks above the main entrance. The wing occupied by Gorham was named ‘Sterling Works’. A few years ago, I was carrying out a bit of research into Gorham’s enterprise in the UK and managed to find the old factory. It was empty at that time and the commercial agent dealing with the property gave me a tour of the building. I am only a very ‘small time’ collector of Gorham items but it felt rather strange to be walking on the floor where Gorham silversmiths once worked in the early 1900s. At the time Gorham moved in, the building was apparently quite modern and had been designed with windows that would allow the maximum amount of light to fall onto the silversmiths’ work areas. The place had been disused for some time when I visited it and was rather shabby and run down. There were still the remains of a few silver workers’ benches about the place but I think these were used by a much more recent company who had worked there manufacturing silver trophies. It is fortunate that when cutting the new road through the area, shown in the front of the photo, the planners were able to avoid demolishing the old building… IP: Logged |

|

asheland Posts: 935 |

Thank you for posting this! IP: Logged |

|

ahwt Posts: 2334 |

Thanks for the post. Is the building in Birmingham? IP: Logged |

|

wessex96 Posts: 56 |

Yes, the building is in Barr Street, Birmingham. It is just on the edge of Birmingham's Jewellery Quarter. IP: Logged |

|

June Martin Forum Master Posts: 1326 |

Yes, thank you so much for posting this UK info. IP: Logged |

|

ellabee Posts: 306 |

What lovely light that is; wonder how much of the space will be "let" and to whom. Thanks very much for this, wessex. I hadn't realized that Gorham had a production center in England. [This message has been edited by ellabee (edited 03-12-2016).] IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

HISTORY OF PROVIDENCE COUNTY In two volumes, Illustrated. VOL. I. NEW YORK: W. W. PRESTON & CO. 1891 pg 618 quote: Gorham "Century Vase" Gorhan "Hiawatha Barge" The following image is from The 1884 Gorham Building, at Broadway & 19th St. IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

quote: IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

The Gorham Sterling Silver Manufacturing Factory Narrated by Martha Stewart IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

Photos of Gorham Factory demolition which began on January 3, 1998. (PDF) IP: Logged |

|

Scott Martin Forum Master Posts: 11520 |

1a.jpg) Click image to supersize [This message has been edited by Scott Martin (edited 05-25-2019).] IP: Logged |

All times are ET | next newest topic | next oldest topic |

|

|

Ultimate Bulletin Board 5.46a

|

1. Public Silver Forums (open Free membership) - anyone with a valid e-mail address may register. Once you have received your Silver Salon Forum password, and then if you abide by the Silver Salon Forum Guidelines, you may start a thread or post a reply in the New Members' Forum. New Members who show a continued willingness to participate, to completely read and abide by the Guidelines will be allowed to post to the Member Public Forums. 2. Private Silver Salon Forums (invitational or $ donation membership) - The Private Silver Salon Forums require registration and special authorization to view, search, start a thread or to post a reply. Special authorization can be obtained in one of several ways: by Invitation; Annual $ Donation; or via Special Limited Membership. For more details click here (under development). 3. Administrative/Special Private Forums (special membership required) - These forums are reserved for special subjects or administrative discussion. These forums are not open to the public and require special authorization to view or post. |

|

copyright © 1993 - 2022

SM Publications

All Rights Reserved. Legal & Privacy Notices |