|

|

|

|

| REGISTER (click here) |

How to Post Photos

|

|

SMP Silver Salon Forums SMP Silver Salon Forums

New members post here New members post here

Handforged Flatware (Page 1) Handforged Flatware (Page 1)

|

This topic is 2 pages long: 1 2 |

next newest topic | next oldest topic |

| Author | Topic: Handforged Flatware |

|

Hand-forger Posts: 28 |

[26-2004] Hi I am new to this forum I have been employed as a Handforger of Sterling Silver Flatware since 1991 first by C.W.Fletchers Silversmiths who are now called Fletcher Robinson they supply Handforged flatware to many companies around the world we are owned by James Robinson IP: Logged |

|

agphile Posts: 798 |

Welcome. I'm delighted to see a spoonmaker from Sheffield join - and equally delighted that hand-forged flatware still continues to be made there. IP: Logged |

|

jersey Posts: 1203 |

Hello & welcome from me also! You are in very good company here with several forgers. I'm sure you will hear from them soon. In the meantime perhaps you would be kind enough to answer 2 questions I have if it's not too much trouble.

Greatly appreciate your response & I thank you in advance, & again Welcome !

IP: Logged |

|

FredZ Posts: 1070 |

Welcome to the forum and it is great to have a silversmith to add the few of us here. Best, Fred IP: Logged |

|

Hand-forger Posts: 28 |

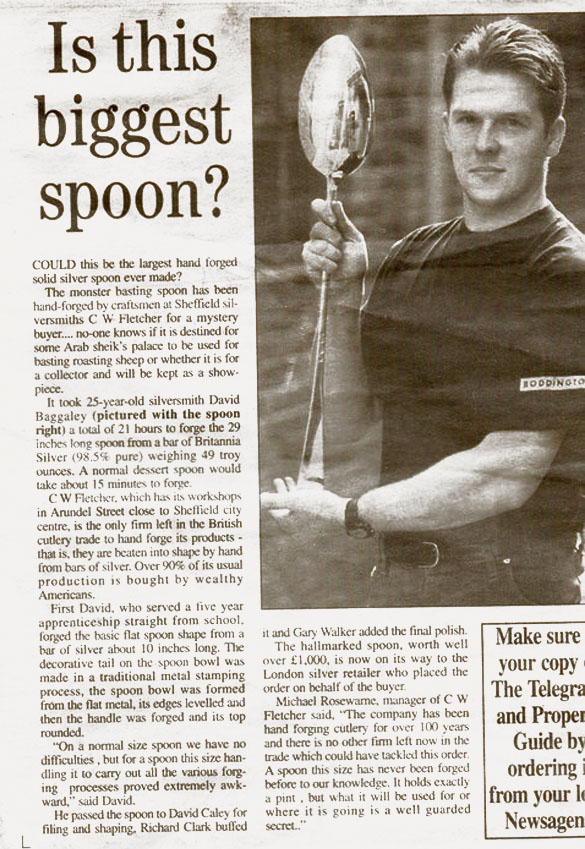

Hi Thank you for your kind welcomes In regards to your question the makers mark is FR It has been this since 2002 before that it was C.W.F I will upload pictures as soon as I have figured it out The 29.5" Basting spoon forged by myself was bought by a London retailer who had taken the commission from a customer in the middle east the name was never revealed I have pictures of it been forged which I will upload as soon as I figure it out Kind Regards IP: Logged |

|

Hand-forger Posts: 28 |

Hi Think I figured how to upload pictures IP: Logged |

|

Hand-forger Posts: 28 |

Hi That worked so now a few pictures of the basting spoon been forged Kind Regards IP: Logged |

|

jersey Posts: 1203 |

Formidable! Thank you so much for your response. Jersey IP: Logged |

|

adelapt Posts: 418 |

Welcome to the forum, and thank you for the photos. As someone who uses hand forged flatware (old and new) daily, I really appreciate the difference of it. It's great to know that the tradition is being kept up (just). Cheers, Adelapt IP: Logged |

|

Hand-forger Posts: 28 |

Thank you @ Jersey yes I am David Baggaley

IP: Logged |

|

PhilO Posts: 166 |

Interesting to see the family resemblance of Fletcher Robinson's sponsor's mark to that of the parent company, James Robinson: IP: Logged |

|

FredZ Posts: 1070 |

David, That is one BIG spoon! I see you hot forge like most Brits do. I can see the advantage on such heavy stock. Makes for faster metal movement. Glad to see you here on the forum. Fred IP: Logged |

|

jersey Posts: 1203 |

Hello again David! A pleasure to meet you! Love your photos, good work! Thank you! Jersey IP: Logged |

|

Hand-forger Posts: 28 |

quote: Hi Phil0 Yes the mark is very similar the letters are the same type. When we first started using the new mark their was a few accidents with James Robinson's work been marked with the Fletcher Robinson mark it was always picked up on at inspection luckily Kind Regards David IP: Logged |

|

Hand-forger Posts: 28 |

quote: Hi Adelapt Thanks for the nice comments its true their are very few company's doing handforged Flatware. hopefully the ones that are left can survive the current economic climate Kind Regards David IP: Logged |

|

Hand-forger Posts: 28 |

quote: Hi Fred Yes all the work is forged hot from a salt spoon to the largest piece but we do the final stage cold Kind Regards David IP: Logged |

|

Hand-forger Posts: 28 |

quote: Hi Jersey I do have my own hallmark D.B.S but it is for my own use its never used by fletchers just my own company My Dad was a silver polisher when I was younger but he left that job then worked in the steel industry then as spray painter My other interests are running my own business which I do at nights and weekends I work very long hours IP: Logged |

|

jersey Posts: 1203 |

Thanks David for the information. Look foward to seeing more great pieces from you. You're still young enough.... As my son would say "Rock On"! Jersey IP: Logged |

|

agleopar Posts: 850 |

Hello David, it is a pleasure to see your work and I had seen the article about you and the spoon. I was taught in a very informal way by a firm in central London in the 70’s, James Potter and Son. I cannot find them as they moved out of London and I doubt they survived. It is great to see a spoon being made the “proper” way – hot! I was asked to copy a 16” stuffing spoon a few years ago and after making the stake for the bowl I got an ingot weighing 10 oz. 6”x 1 ¼” x ¼”. I thought it would be a long job but was surprised that because the ingot was so big it held the heat longer and heated back up very quickly and it seemed for so large a spoon to go quickly. I am no the fastest so I was happy that it came in at about 11 hours. Now after 10 or so and 2 large ladles that I have also done recently, they take me 7 hours and weigh 7 oz. Can I ask the ingot weight and dimensions and I think the article said how long it took to make but I do not remember. Any other insight you would like to throw in I would (and I’m sure all here) be very interested, like how you made the stake for it and cranked the handle etc. Again it is a pleasure to see this, I am a fan of good old English spoon making which has such a tradition. That makes me think of another question – who taught you and who taught him?? I am sure in the firm but is the history ever discussed? Sorry to go on but I have just seen the post so I am late to the conversation. IP: Logged |

|

Hand-forger Posts: 28 |

Hi The following is the newspaper article  I will add more details later IP: Logged |

|

blackbird Posts: 17 |

David, I worked at James Robinson for seven years 1998-2005. During that time they became full owners of the workshop in Sheffield, which was a really big deal for the store. While I worked mostly with the antique jewelry, I also had the privilege of selling Fletcher's outstanding hand-forged flatware. During that time, we also sold handmade reproduction silver trays and salvers, and I heard that it was getting harder to find flat-hammerers (is this a term?). I forget who made the trays, but they were/are of incredible quality. Anyway, great to 'meet' a Fletcher's alumnus. Jackie IP: Logged |

|

Hand-forger Posts: 28 |

quote: Hi agleopar The weight of the ingot was 49oz and it took 21 hours to forge it became quite a danger when it was red hot so i gave it a lot of respect before this the largest item i had forged was a soup ladle these are 13 inches long and take about 1.5 hours to forge we did spend quite a bit of time talking about it. We made the die for the tail and punch for the bowl the bowling punch was made from a block of wood and cast in steel it was then bowled in a drop stamp one funny point was when they polished it they had to put the handle out of the window. in regards to the history Nicholas Bartholomew worked circa 1550 I was apprenticed at 16 in 1991 by Colin Wallace who was 60 and was fletcher's only remaining forger at that time. I was his second attempt as the first one left. Colin also taught Robert Allen after me and then retired aged 72 he started work for them aged 14 he was apprenticed to Charlie Mcnair who had been taught by Charles IP: Logged |

|

Hand-forger Posts: 28 |

quote: Hi Jackie It sure is a small world and its very nice to hear from yourself. I only ever spoke to eddie joan and norma and that was only when they visited probably every 2years or so. What did you do after leaving james robinson Kind Regards David IP: Logged |

|

agleopar Posts: 850 |

David, many thanks for the reply, it is not often that the "biggest" of something is attractive but this spoon is. 21 hours is impressive and I can imagine the acrobatics it would take to stay out of the way of the hot spoon when your working it. The last questions (I promise), the finished weight and why 29”?Do you use Britannia regularly? The history of the firm is fascinating, the Chawner name being one I have seen on spoons. Your apprenticeship to Colin Wallace and lineage of masters has become a rarity – I know you are young but is there talk of you training the next generation? Thank you for the replies and your time. If you ever come to the states please consider a visit with some US smiths… all 5 of us! IP: Logged |

|

Hand-forger Posts: 28 |

Hi I don't remember what the finished weight was but I will try to find out for you The size was requested by the customer the bowl also had to hold exactly one pint it was made in Britannia as that's what they had asked for We normally work with sterling but if the customer requests something else we try to oblige There are currently no plans that I know of to start training the next generation. I just hope history does not repeat its self or worse Thanks for your invite that would be awesome one day I have a question also how many hand-forgers have you come across in the USA and England or other country's and how many forge hot versus cold do you or anyone else know the answer to this Kind Regards David IP: Logged |

|

agleopar Posts: 850 |

Thanks David for the info and since the request for one pint bowl size seems to have been the overriding design request it makes me think that this is going to be used for some strange drinking game?? Just kidding but it would be fun to know for who, what for and why this was commissioned. As the trade is now almost extinct in the US, by that I mean almost all the hollowware and cutlery firms are out of business and there is only one doing hand forged flatware. There are 3 shops that I know of, the only one still a business as opposed to an individual is Old Newbury Crafters in Amesbury, MA (Middle Tom on the forums works there). Then the others are Peter Ericson in Gardiner, MA, he is the grandson of a flatware man who worked for the Stone shop (closed in the 50’s). The last is Randy Stromsoe, who took over Porter Blanchards shop in CA. There are other individuals sprinkled around the country, some are making very nice flatware, others are making very basic stuff… None that I know of are hot forging and my personal theory is that those who do it cold learned from a Scandinavian master. There were a great deal of very good silversmiths teaching in this country in the 50’s who were from that part of the world. Again my theory and not scientific but the only logic I can come up with… I think I have jokingly challenged Middle Tom to a race hot vs. cold but if I had you as my contestant it sounds as though it would be over before it started! So maybe in the future you could help me get my times for a tablespoon down to under a half hour for the forging? That finished weight on the big spoon interests me, even just a guess. IP: Logged |

|

Dale Posts: 2132 |

Welcome to the forum. And thanks for the wonderfully enlightening posts. Who is the market for hand forged flatware? Are there many customers or just a few die hard collectors? How do you market and sell your creations? Just wondering how the trade is holding up. Not training young smiths is sad. IP: Logged |

|

Dale Posts: 2132 |

I am not so convinced that the trade is 'almost extinct' in the US. From what I can tell, there are smiths producing both custom order and mass market (no pun intended) liturgical silver. Just who they are is rather murky, but the product is out there. There are also quite a few smiths who produce jewelry, because that is where the market is. Additionally, a shop in South America offers to reproduce antique silver to order. From the pictures at their site, they do excellent work. While the tableware makers are in decline, other venues are viable. IP: Logged |

|

FredZ Posts: 1070 |

Randy Stomsoe recently completed place settings for 12 for a client. I have not heard from Peter Erickson and I suspect he still gets the odd commission. Baby spoons and sets are always in demand for the descriminating client. IP: Logged |

|

agleopar Posts: 850 |

Dale, sorry I was not clear, but also I am a bit of a snob and really was not counting machine made silver or jewelry. There are a ton of terrific jewelers in this country but I was focused on holloware and flatware. Also I am not sure how many companies are left after Lunts demise. I am very pessimistic about the trade. It would be a good exercise in another post to count them up and redo it every year. As for hand made holloware and individual artist craftsmen the Society of American Silversmiths has anywhere to 100-150 current or recent members and there are another 200 or so out there. But to me that is scraping the bottom of the barrel when you compare it to England and 3-4,000 smiths still! So I think the trade, as a whole, in this country cannot go any further down... IP: Logged |

|

middletom Posts: 467 |

handforger, Welcome to this discussion. I just came across your thread. I am Geoff Blake and go by middletom here. I have worked at Old Newbury Crafters for nearly forty years. We forge cold, except that punch and soup ladles are hammered hot the first couple stages because of the amount of silver to be moved. Agleopar is a thorn in my side because he is under the mistaken impression that he could beat me if he were hammering hot and I cold. As I mentioned in another thead today, Arthur Stone, from whom our I enjoyed seeing the pictures of your forging of that great spoon. Wonderful! I've not done anything larger that a punch ladle, but if requested, I'm sure I could go larger. My best to you. It good to see someone so young being involved in the craft. middletom IP: Logged |

|

Hand-forger Posts: 28 |

quote: Hi agleopar I agree it must have been for a drinking game no pub should be without one lol I did wonder myself but have never been told the name of the end user or its purpose I have searched the internet many times to see if its out there but as of yet no luck In regards to the trade of handforged Silver flatware its looking a little thin on the ground when I first started work The company was under the impression that there where no others left the advent of the internet has changed that belief but its looking like the craft of hand-forging sterling silver flatware is close to extinction A table spoon under half an hour no problem The weight for the large spoon finished was 37oz Kind Regards David IP: Logged |

|

Hand-forger Posts: 28 |

quote: The market for Hand-forged flatware is mainly the top end of the market the rich n famous we do have a few collectors but they are normally buying antique hand forged flatware and just can't find that missing piece to complete the set so settle for a antique reproduction we also do commissions for designers who design the flatware and then we make it for them. I agree that not training the next generation of Hand forgers is sad but they need to be selling more to be able to do this but we are both quite young so there's a bit of time yet At what point am I able to post in other area of this forum? as there are few I Would like to join in with but can't. IP: Logged |

|

Hand-forger Posts: 28 |

quote: I Have not heard of peter erickson is he in the usa? IP: Logged |

|

Hand-forger Posts: 28 |

quote: Thats intresting what the name of the company or web addy? IP: Logged |

|

Hand-forger Posts: 28 |

Hi Middletom It nice to meet another Handforger your company was the first one I came across whenI started searching Your recent post about your company needing young blood is very sad and is one our company faced back in 1991 My master Colin Wallace was 60 and also wanted to retire luckily it worked out for them Kind Regards David IP: Logged |

|

Dale Posts: 2132 |

The discussion on the South American company is here (Company in Peru). One great difficulty we face here is that we do not link to commercial enterprises, which makes discussing the current state of the trade very difficult. IP: Logged |

|

agphile Posts: 798 |

As a user rather than a maker of hand-forged flatware I have been keeping out of this thread, but thought I ought just to mention that in England Wakely and Wheeler,formerly of London but now in a workshop in the countryside just outside, continue to produce flatware. When I visited getting on for a year ago Jeff Francis, the spoonmaker there, had an apprentice who was coming to the end of his time and must by now be qualified. The apprentice was planning to make a giant spoon for his "masterpiece", but I suspect not as giant as yours. IP: Logged |

|

FredZ Posts: 1070 |

David, Peter Erickson has a shop in Gardner, Massachusetts. He apprenticed to his Grandfather who had worked in Arthur Stone in his shop. Peter is a member of the Society of American Silversmiths and he has a website. Fred IP: Logged |

|

Hand-forger Posts: 28 |

quote: Hi Dale Thank you for that information I managed to find the web site from that thanks they make antique reproduction holloware I could not find any flatware Kind Regards David IP: Logged |

|

Hand-forger Posts: 28 |

quote: Hi Thanks for that I met jeff a few years ago we helped them with a project that they needed dies for from what I remember they forge cold Kind Regards IP: Logged |

|

middletom Posts: 467 |

Thank goodness, someone who forges cold. Did you see that, Agleopar? It's not just us colonials. middletom IP: Logged |

|

agphile Posts: 798 |

I think they actually forge hot. IP: Logged |

|

agleopar Posts: 850 |

Ha, ha, Tom - Agphile backs me up! Seriously its just a theory but Stone was not (as far as I know) a flatware man and I am betting that who ever started making it in his workshop was trained by an American master. My English master, Michael Murray was brilliant at raising and chasing but made few spoons and in the Arts and Craft style (what he called a glue job). Until I toddled off down the road at my lunch break to James Potter and Son I had never seen hot forging. David, thank you for the finished weight of the big spoon it now has an image in my mind that as a maker and collector of spoons I just like knowing... I can now say with real authority that I know of the largest spoon in the world! And I know who the maker is!! IP: Logged |

|

Richard Kurtzman Moderator Posts: 768 |

quote: Hand-forger, There is a protocol for elevating the posting privileges of a New Member to the rest of the SSF public forums. IP: Logged |

|

middletom Posts: 467 |

Agleopar, You could be right. Stone worked at Durgin (sp.?) when first in this country and I seem to recall reading somewhere that he and George Blanchard worked together at Frank Smith silver company. Perhaps Blanchard was the actual flatware man in the shop whereas Stone's training was in hollowware and chasing. I've seen a copy of the Harvard film showing the making of a spoon and the person in the film used the very same techniques we at ONC do. But, FredZ sent me a description of flatware making written by Mrs. Stone and she described forging with the peening end of the hammer head rather than the broad face. It appears two different styles were used at Stone's shop. Fred also told me that Peter Ericson forges with the peening end. I don't know why the differences except perhaps there were, at different times, masters of flatware who came from different schools. Well' those are just some thoughts and I may be out in left field. middletom IP: Logged |

|

agleopar Posts: 850 |

Tom, all my thoughts are conjecture - I just find it so interesting that the GB/US schools are so distinctively divided between hot and cold. Does anyone know how forging is done in the Scandinavian countries? IP: Logged |

|

middletom Posts: 467 |

Agleopar, This whole discussion has peaked my interest in knowing why the different techniques here and across the pond. And, as you have mentioned before, the size or configuration of the stock used to make a piece differs here from there. I wonder if there is available a source of information either here or in England that could shed some light on the why of the different techniques. There must have been some things written down over the years, but I would not know how to go about getting at it. middletom IP: Logged |

|

Randy Stromsoe Posts: 8 |

quote: Hey Tom et all - I've been trying to figure out how to respond to this thread and post a few pics for days now. This has been a fun thread to follow. Hope you are all doing well! Randy IP: Logged |

|

Randy Stromsoe Posts: 8 |

HELP! I am a silversmith, not a tech wizard. Have been trying to send a response to Middletom for days and many many photos of flatware progressions, hammers etc. Where do they go when I press send? Your flatware tread has been fun to read and I am trying to jump in. R IP: Logged |

This topic is 2 pages long: 1 2 All times are ET | next newest topic | next oldest topic |

|

|

Ultimate Bulletin Board 5.46a

|

1. Public Silver Forums (open Free membership) - anyone with a valid e-mail address may register. Once you have received your Silver Salon Forum password, and then if you abide by the Silver Salon Forum Guidelines, you may start a thread or post a reply in the New Members' Forum. New Members who show a continued willingness to participate, to completely read and abide by the Guidelines will be allowed to post to the Member Public Forums. 2. Private Silver Salon Forums (invitational or $ donation membership) - The Private Silver Salon Forums require registration and special authorization to view, search, start a thread or to post a reply. Special authorization can be obtained in one of several ways: by Invitation; Annual $ Donation; or via Special Limited Membership. For more details click here (under development). 3. Administrative/Special Private Forums (special membership required) - These forums are reserved for special subjects or administrative discussion. These forums are not open to the public and require special authorization to view or post. |

|

copyright © 1993 - 2022

SM Publications

All Rights Reserved. Legal & Privacy Notices |